Cottonstix® Cotton Movers: Heavy-Duty Spears and Frames Built for Today’s Growers

Why AG-GO Cotton Frames Matter

Cotton harvest doesn’t end at the picker. Once bales are wrapped and staged, they need to be transported, stacked, and loaded—often under tough field conditions. Traditional equipment not built for cotton can struggle with the unique demands of these massive bales, leading to downtime, damage, or even safety risks. Cotton movers like PRO-Link’s Cottonstix® system provide a specialized solution. With heavy-duty cotton spears engineered to pierce and stabilize bales and reinforced cotton frames for secure handling, growers can count on reliable performance in every step of the post-harvest process.

How Heavy Are Cotton Bales?

The strength of cotton movers really matters when you understand the weight they’re expected to handle: Round cotton modules (commonly seen today) weigh between 4,500–5,000 pounds each. Traditional square bales can weigh anywhere from 480–600 pounds each. Module-sized stacks may weigh well over 10,000 pounds.

Because of this, smaller equipment such as skid steers simply can’t lift cotton safely—they lack both the weight and capacity. That’s why tractors and loaders, paired with the right cotton frames and spears, are the trusted solution across the cotton belt.

Cottonstix® Cotton Spears: Engineered Strength

At the heart of every cotton mover are the spears themselves. PRO-Link’s cotton spears are designed with the same rugged engineering that has made our hay bale spears an industry standard. The difference lies in tailoring the design to cotton’s unique bale size and density.

Durable Construction: Cottonstix® spears are forged from high-strength steel, heat-treated for wear resistance, and precision-sharpened for easy penetration.- Optimized Length & Diameter: Built for large round cotton modules, these spears offer the balance of penetration depth and stability needed for thousands of pounds. Secure Mounting: Spears lock into AG-GO’s cotton frames, reducing spear flex and ensuring bale stability even across uneven terrain.

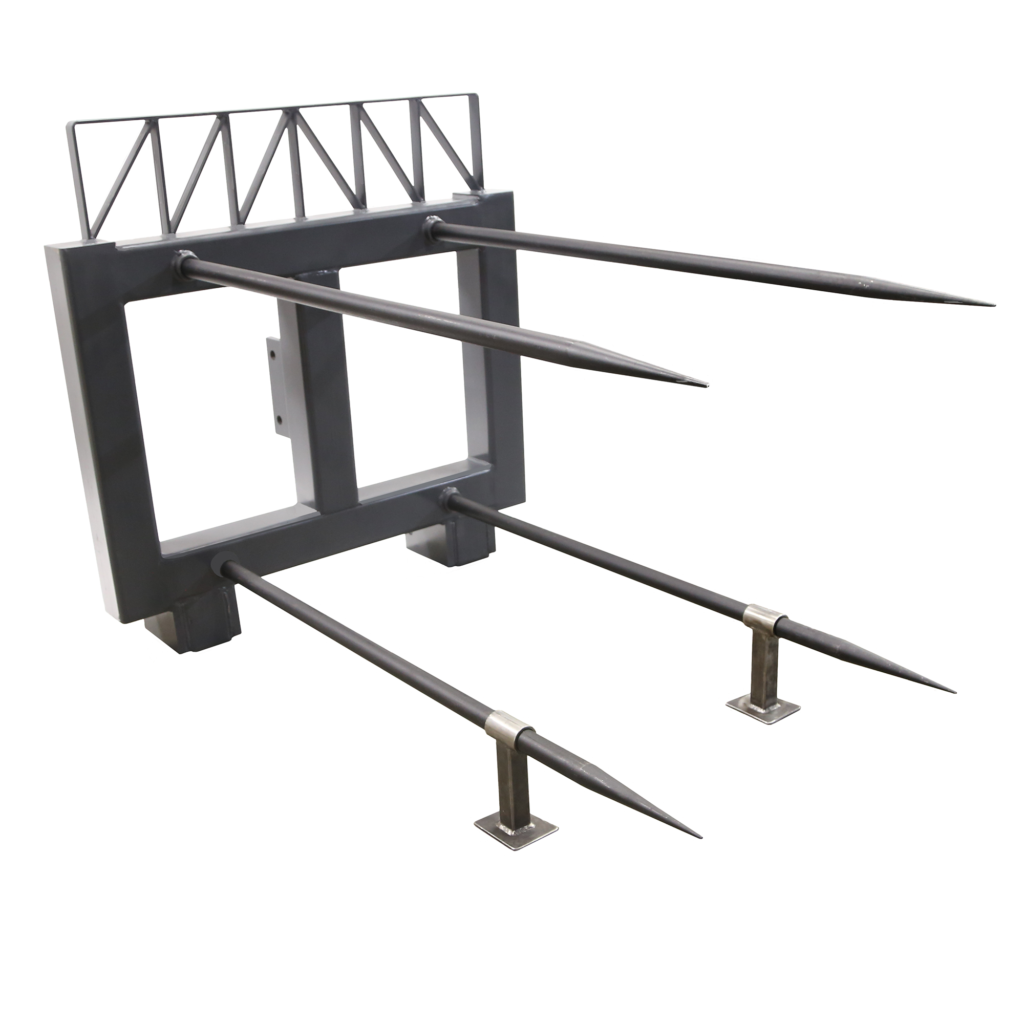

Front and Rear Style Cotton Frames The power of the spear is only as strong as the frame that holds it. That’s why AG-GO Attachments offers both front and rear style cotton frames to match the needs of your equipment fleet.

Front Mount Cotton Frames:

Designed for tractors and loaders, front-mount cotton frames allow operators to spear, lift, and transport cotton bales directly from the cab. Built with reinforced steel construction and universal mounting compatibility, these frames give growers a reliable tool to handle even the heaviest bales.

Rear Mount Cotton Frames:

Rear-style frames provide balance and extra hauling capacity. Mounted on the tractor’s rear, they let operators move additional bales while keeping the front loader free for stacking or loading trucks. This dual setup is one of the most efficient systems for large-scale cotton handling. Both frame styles are manufactured to PRO-Link’s high standards, under the AG-GO brand, with powder-coat finishes to withstand field conditions and years of service.

Efficiency in the Field

Imagine harvest crews trying to move wrapped cotton bales without the right equipment—inefficient stacking, wasted time, and potential bale damage. With Cottonstix® cotton frames and spears, the process becomes streamlined:

1. Spear the Bale: The spear penetrates cleanly without tearing wrap or compromising bale integrity.

2. Transport Securely: Frames provide stability, ensuring the bale stays steady on uneven terrain.

3. Stack or Load: With both front and rear frames, operators can double their handling capacity in a single trip.

For operations with tight deadlines and large bale counts, these efficiencies add up to real savings in labor, fuel, and machine wear.

Built for Growers, Backed by PRO-Link & AG-GO

PRO-Link isn’t just a supplier—we’re a partner in agriculture. With decades of experience in building attachments and farm solutions, we understand the demands cotton producers face. Every cotton mover we build undergoes strict quality control, ensuring you get equipment you can trust season after season. What sets PRO-Link apart is not only the quality of our cotton spears and cotton frames, but also the flexibility to adapt to your specific needs. Whether you’re outfitting a new fleet or upgrading older equipment, our AG-GO Attachments line is here to provide solutions that fit your operation.

Why Choose Cottonstix®?

Durability:

Built from premium materials designed for long-term use.

Efficiency:

Front and rear frame options increase hauling capacity and reduce downtime.

Versatility:

Compatible with multiple tractor and loader setups.

Proven Performance:

Trusted by growers across the cotton belt for reliable bale handling.

When it comes to cotton harvest, cutting corners isn’t an option. Cottonstix® movers give you the confidence that every bale will be moved safely and efficiently.

Final Thoughts

The cotton industry demands tools that can handle heavy loads, tough conditions, and the relentless pace of harvest season. With Cottonstix® cotton spears and AG-GO cotton frames, PRO-Link & AG-GO provides growers with a dependable, field-tested solution for all their cotton moving needs. Whether you’re hauling from field to gin, stacking for storage, or loading for transport, Cottonstix® equipment is built to get the job done right the first time. When you think cotton movers, think PRO-Link and AG-GO Attachments—where quality, performance, and grower success always come first.